Design

“Details matter- it’s worth waiting to get it right.”

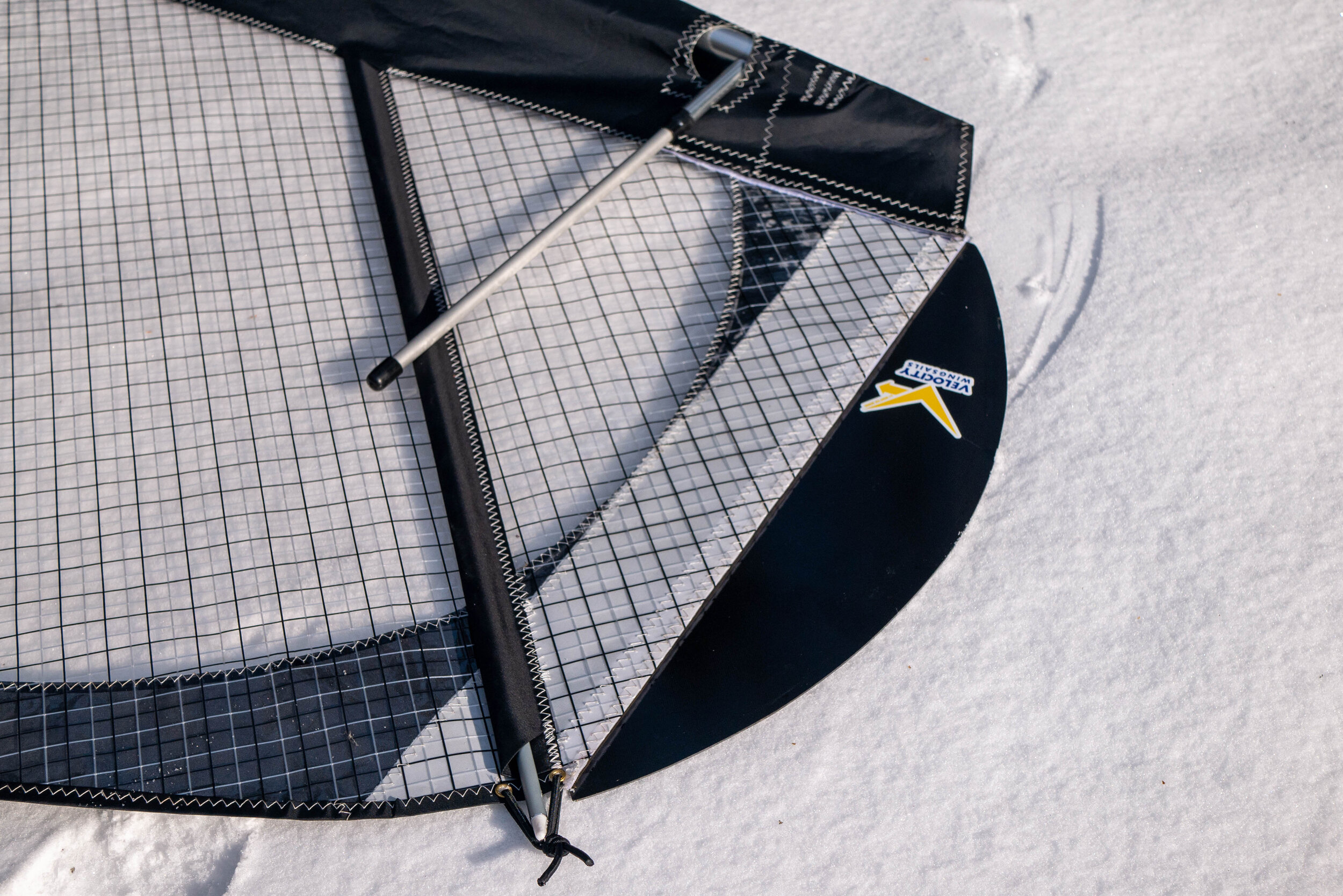

Starting with the concept of a hand held wing sail, and going over every single square centimeter,

Velocity has redefined the concept of the hand held wing sail with a revolutionary new design.

North Wing not only makes sails for its own line of gliders and motorized weight shift aircraft, but it also does contract stitching for other major brands of ultralight aircraft. The quality of work coming out of their sail loft is unrivaled.

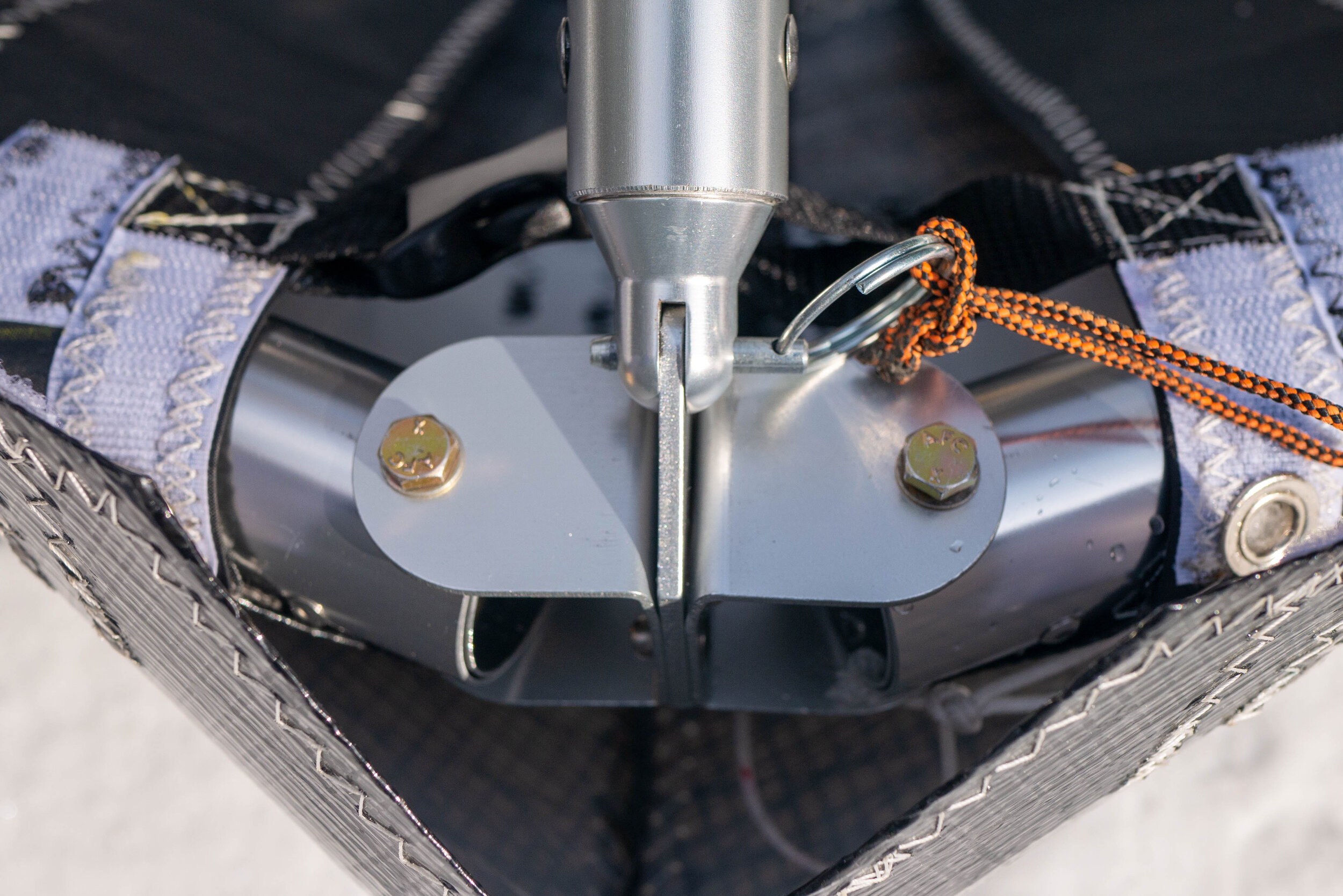

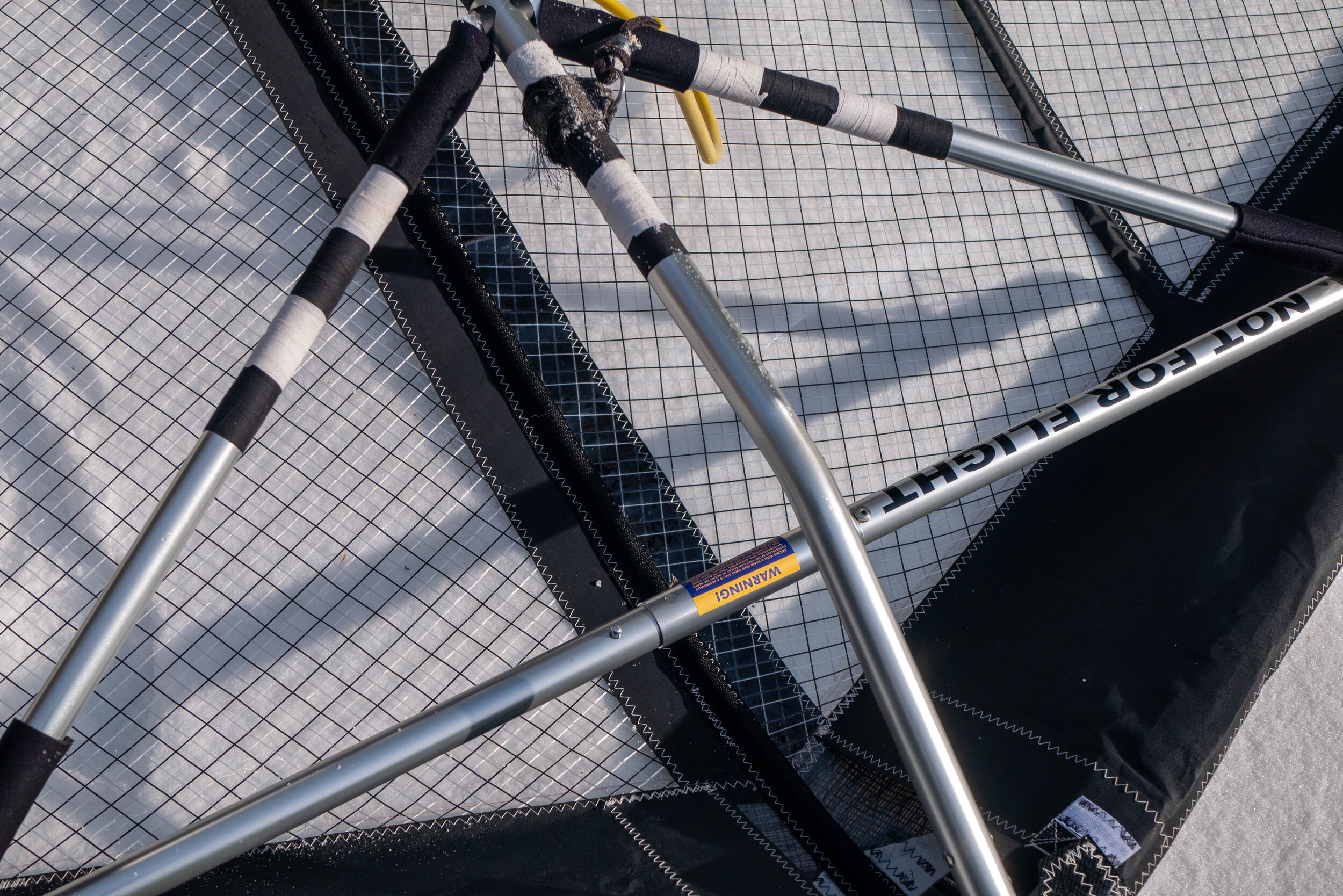

AIRFRAME

This is the structure that supports the entire rig. It needs to be right. Velocity wings draw upon the expertise of those who have hung their lives in the balance high above the ground in hang gliders for this critical component. So much has been learned over the decades about what works, and what doesn’t that it only makes sense to take advantage of this vast body of knowledge.